News and Articles

Related Product

Share Article

Is it Better to Have Thicker or Thinner Thermal Conductive Silicone Pad?

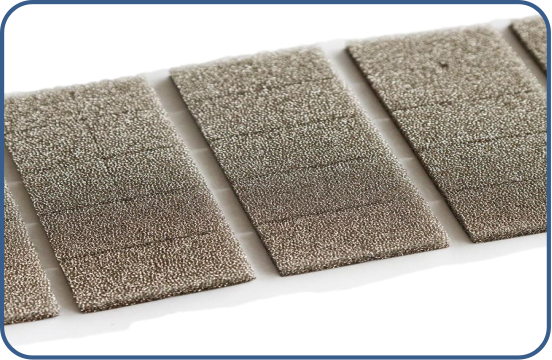

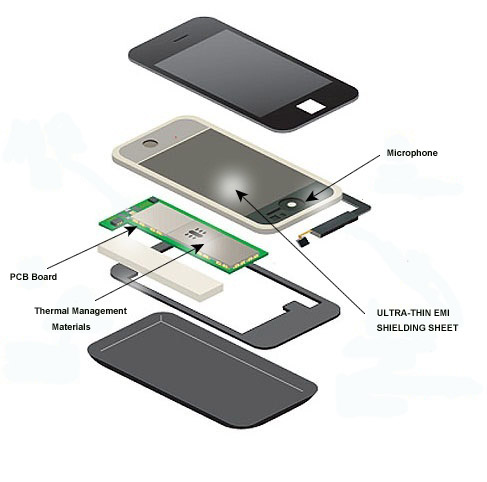

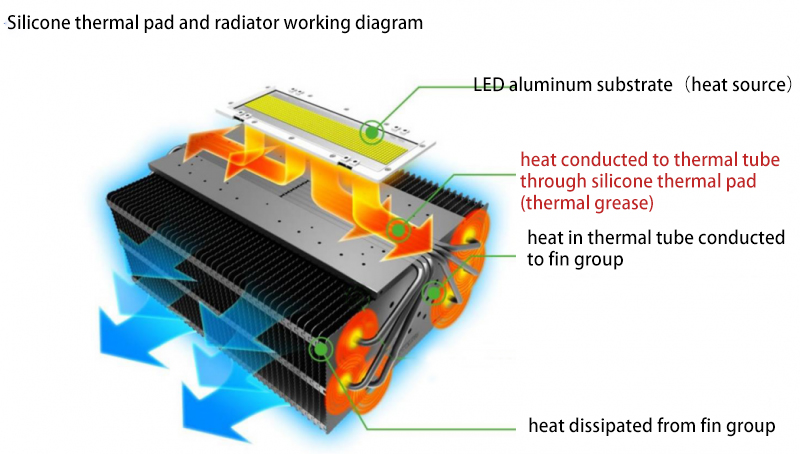

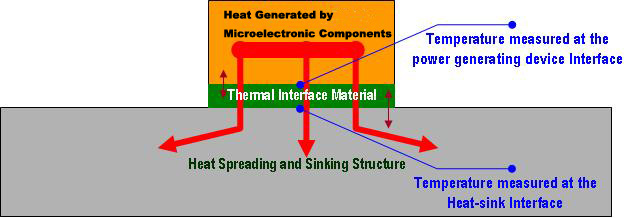

Thermally conductive silicone pad is one kind of thermally conductive interface material, and its main function is to bridge the gap between the heat sink and the heat source, or to reduce the contact thermal resistance between the two. According to the Fourier theory of thermal conductivity, the thermal resistance is inversely proportional to the thickness of the material, the thicker the material, the higher the value of the thermal resistance, so when choosing to use it, it should be the thinner the better.

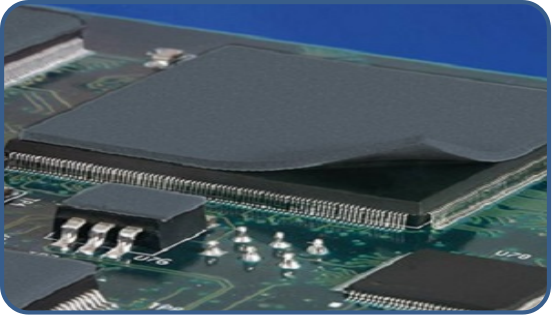

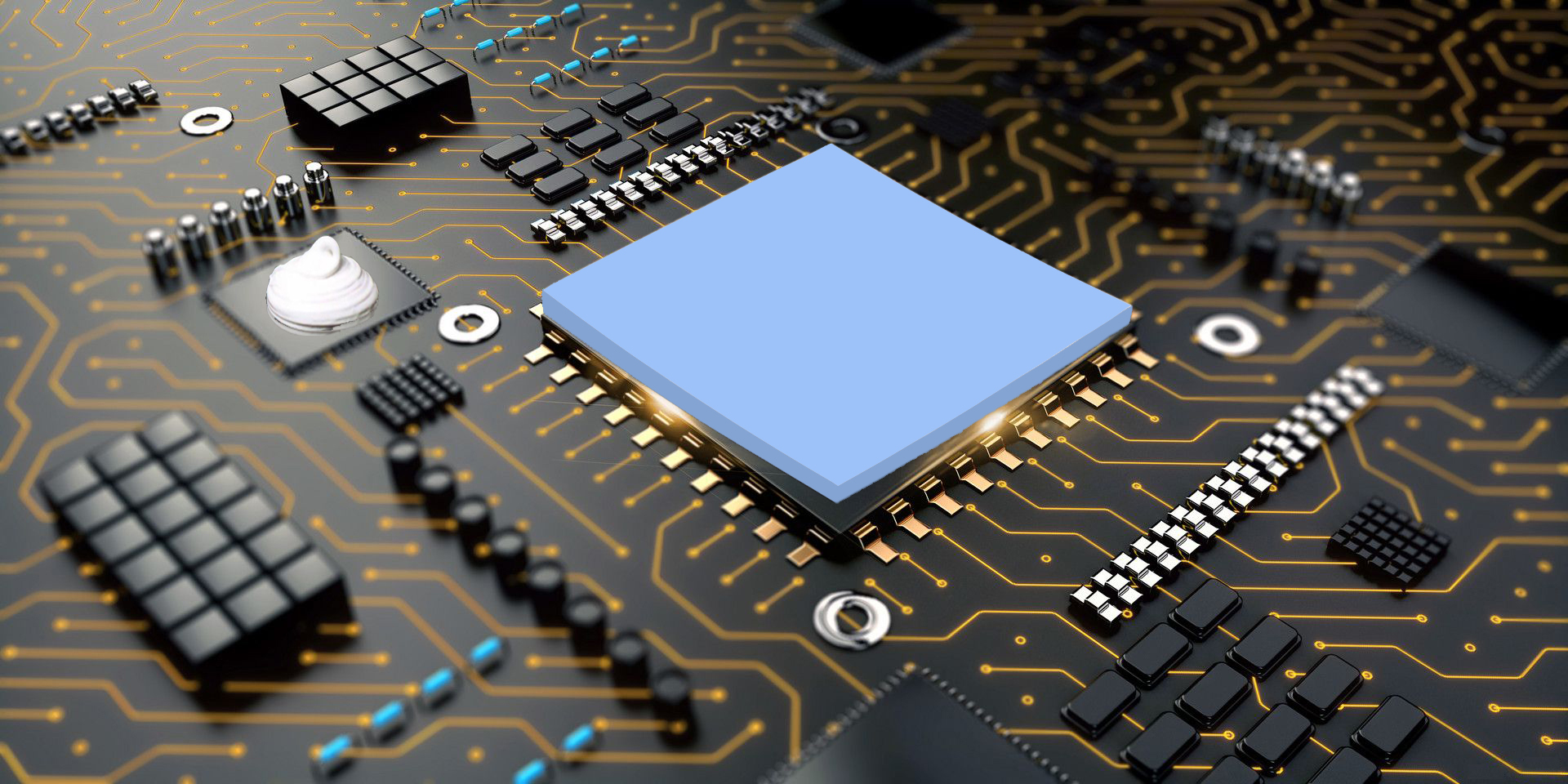

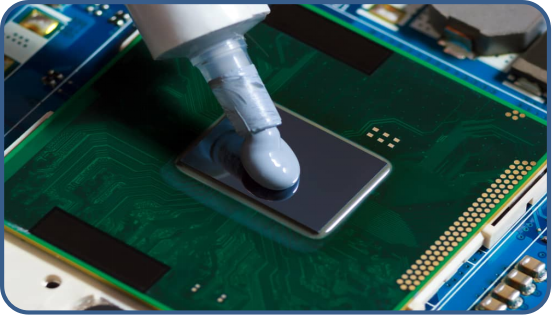

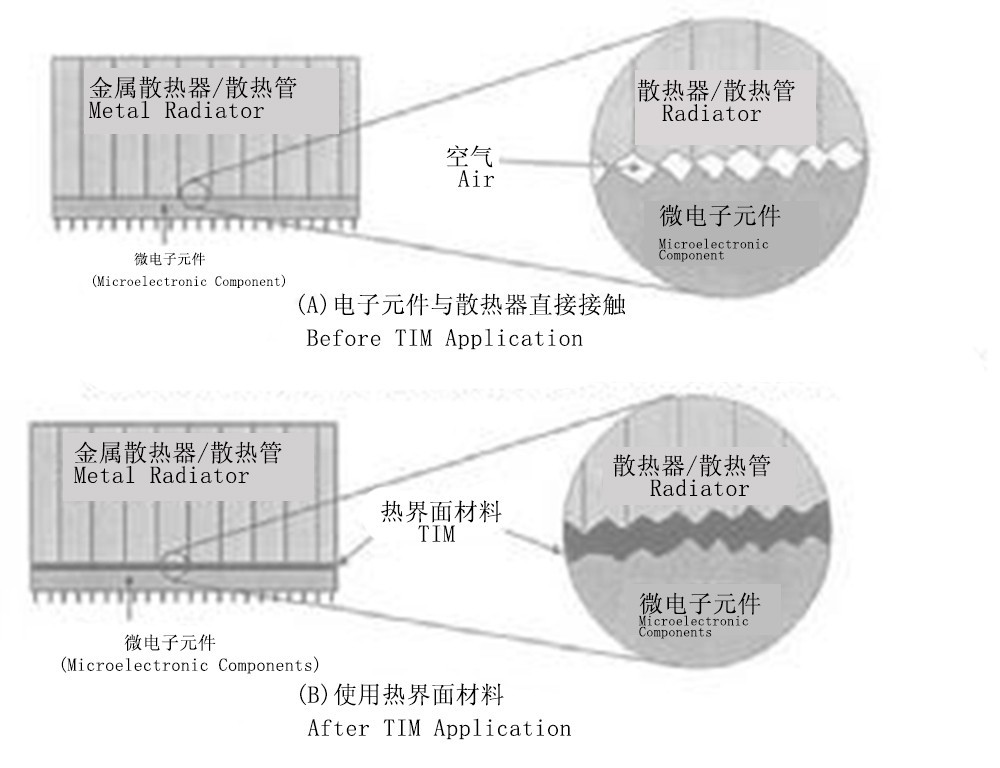

Thermally conductive silicone gaskets are placed between the heat generating component (e.g. CPU, GPU, etc.) and the heat sink component to fill the gap between them for heat transfer.

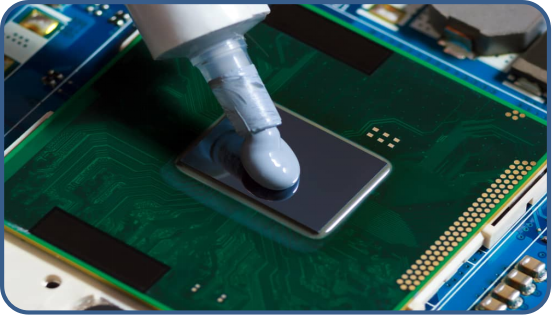

This is because the surface of the heating element and heat sink is not as smooth as the naked eye sees, there are a lot of gaps, the air between these gaps is a poor conductor of heat, which needs to be filled with thermally conductive silicone sheet.

Since we have to fill the gap, so the thermal conductive silicone film to be a little thick, but this "a little" is how much? Specifically, it is to be thicker than the gap between the heating element and the heat sink!

For example, the minimum gap between the radiator and the heat source (after pressure), if it is 1.0mm, then you can choose 1.2mm thermal shims, so that after the assembly, in order to make the thermal shims to completely fill the gap between the two. If you choose 1.0mm and below thermally conductive gasket, after assembly, there is still the existence of the gap, the formation of a large number of thermal resistance. Then the use of thermally conductive shims is not very meaningful.

In addition, there is something else to consider:

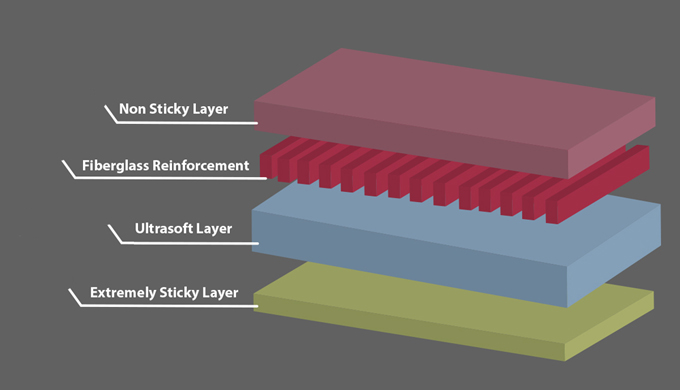

(1) the thermal conductivity of the thermal conductive gasket itself, the same thickness, the higher the thermal conductivity, the lower the thermal resistance value, the better the thermal conductivity.

(2) the surface hardness of the thermal pad, the smaller the hardness, the softer the product, the better the service of the heat sink and heat source, the higher the infiltration performance, the smaller the contact thermal resistance, the better the thermal conductivity.

(3) The resilience of the thermal pad, or the compression of the thermal pad variable. The better the resilience, the smaller the compression variant, the stronger the ability of the material to keep the gap filled. The better the thermal conductivity.

Of course, there are other factors, such as the tear strength of the surface, to ensure that the material can not be broken in the assembly process, resulting in fractures or gaps, which are also prone to form a large thermal resistance. In short, the sole purpose of using a thermally conductive spacer is to reduce the contact thermal resistance between the heat sink and the heat source. Selection should refer to both the various parameters of the thermal shims, but also to the actual assembly process parameters.