Main Markets

Related Product

Share Article

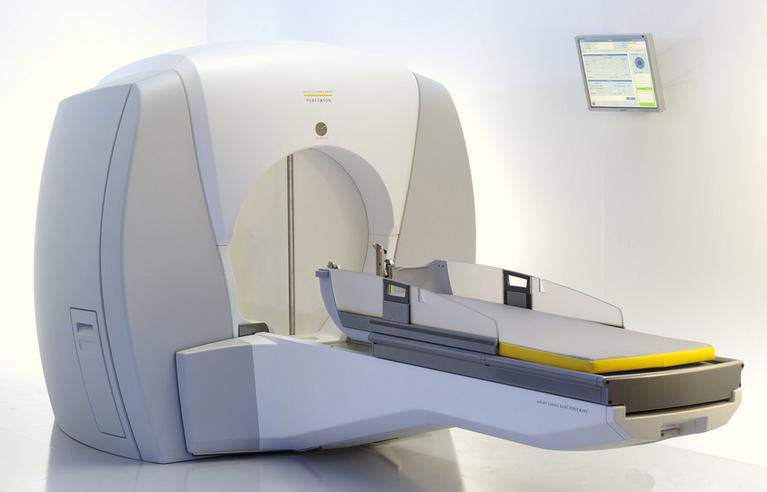

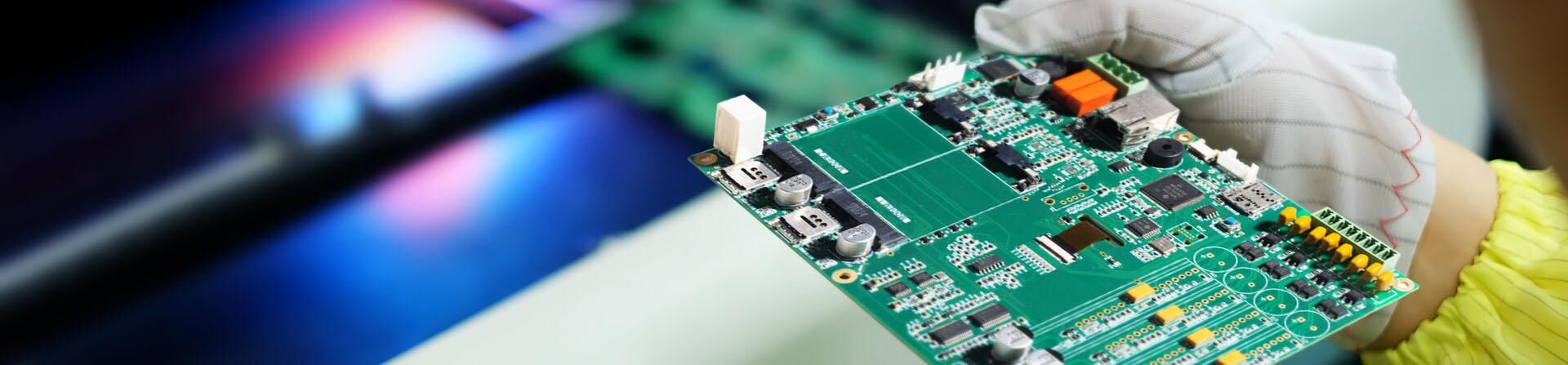

Medical Device Thermal Management Materials

Thermal Management Solutions in Medical Device

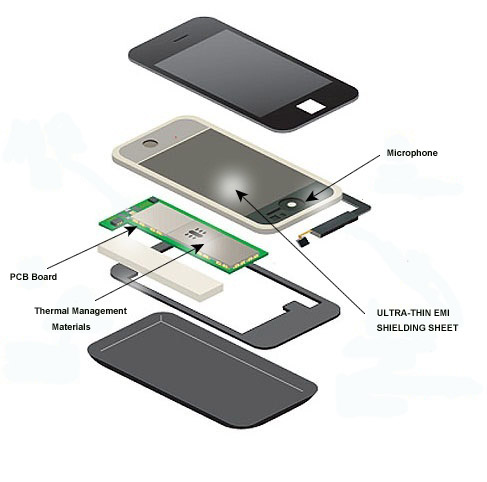

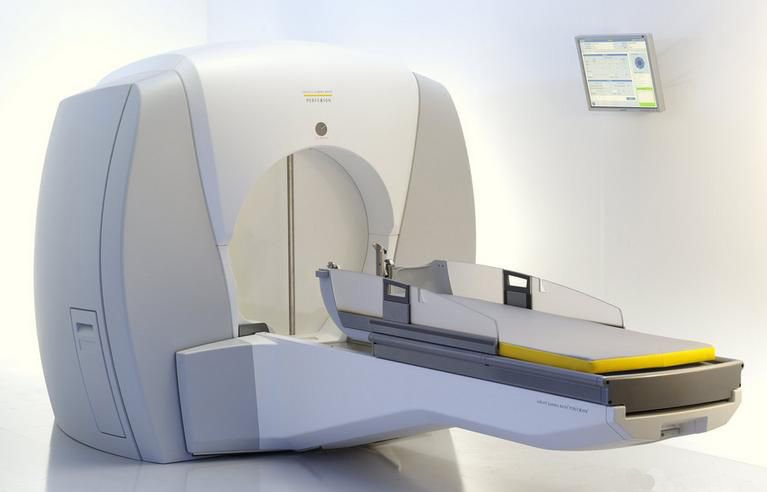

Medical devices are trending toward miniaturization, driven by portability, performance and safety factors. As instruments get smaller, design engineers face new challenges in meeting their project’s performance, size, weight, operating temperature, noise and budget requirements. Each of these factors also impacts thermal management technology choices. The right thermal management solution can play an important role in helping engineers meet all project requirements and design the best medical device.

Importance of Cooling Medical Devices!

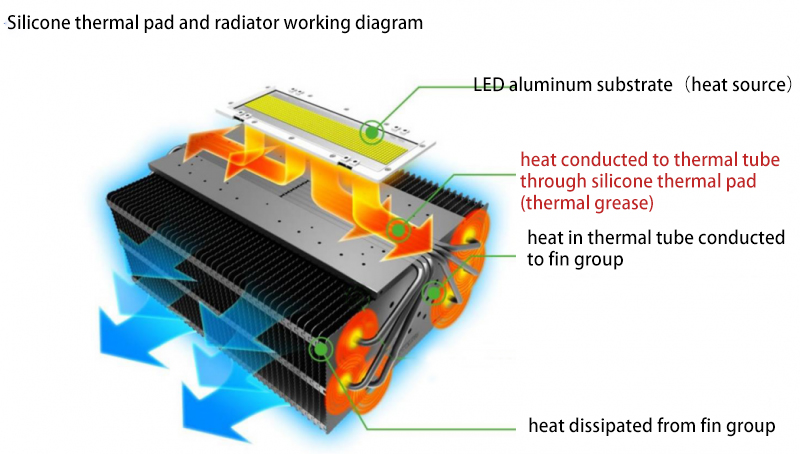

Thermal management allows heat to be efficiently moved, spread and dissipated, improving system reliability, speed, precision and service life while also helping designers reduce device packaging size, weight, energy consumption, noise and bioburden concerns. Advanced thermal management also allows designers to maintain consistent temperature control and increase the power level of a device without increasing the operating temperature.

Thermal Management Materials - Save Money, Get Better Quality

Because of the many design objectives small medical device engineers must consider, passive thermal management solutions are often an ideal solution for these projects. They solve complex cooling problems in small spaces, reduce the opportunity for spreading or harboring microbes and do not require a power source. Passive technologies have long-term reliability and can offer serious savings on service and maintenance costs – plus the cost benefits that come along with extended equipment lifetime.

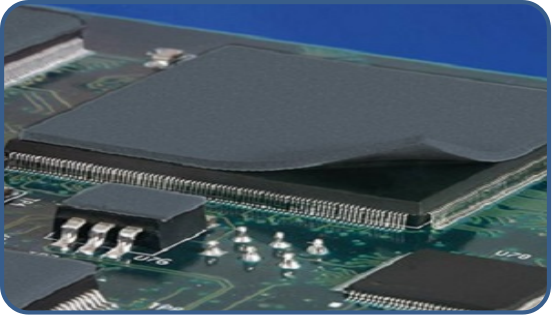

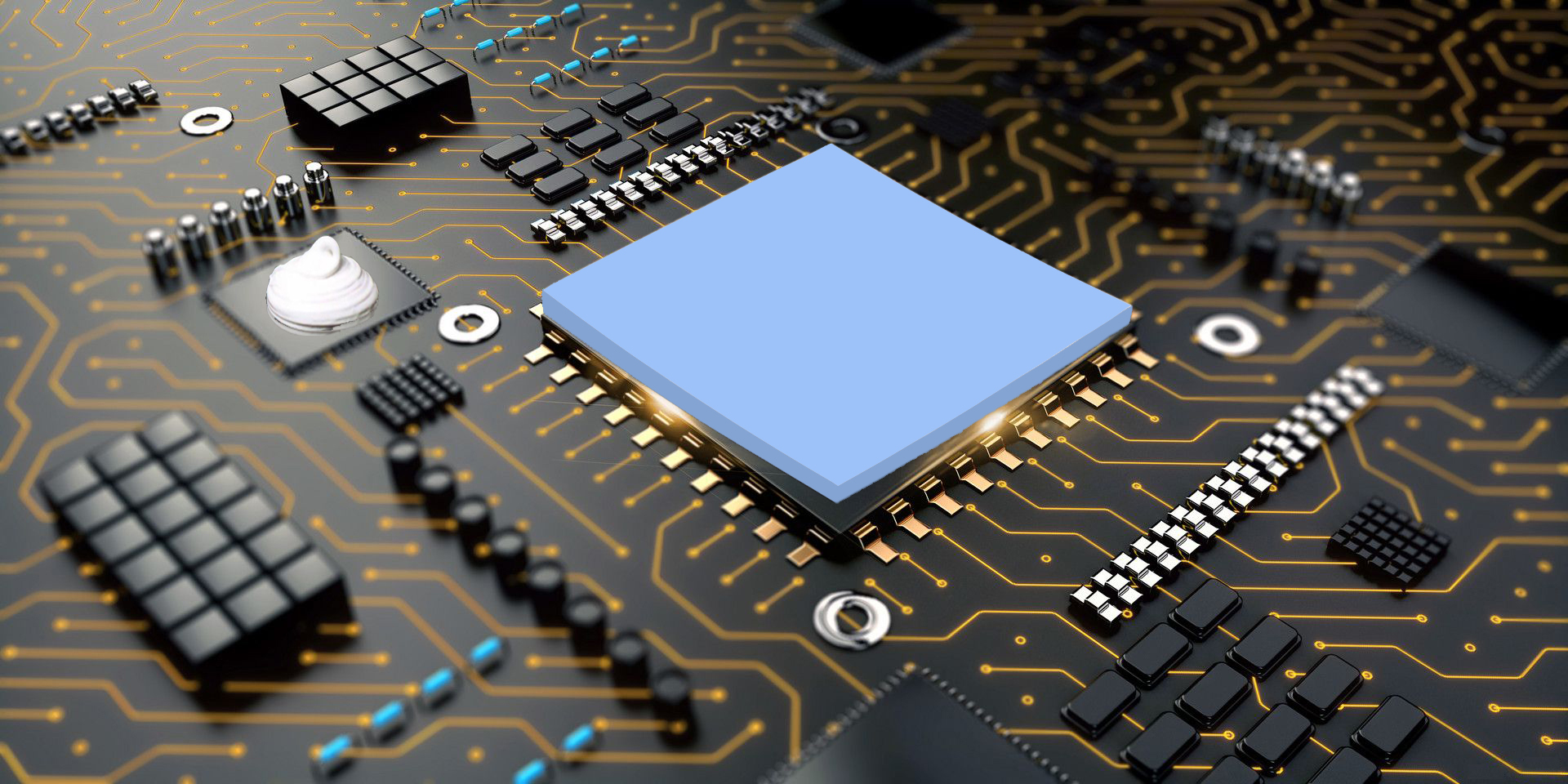

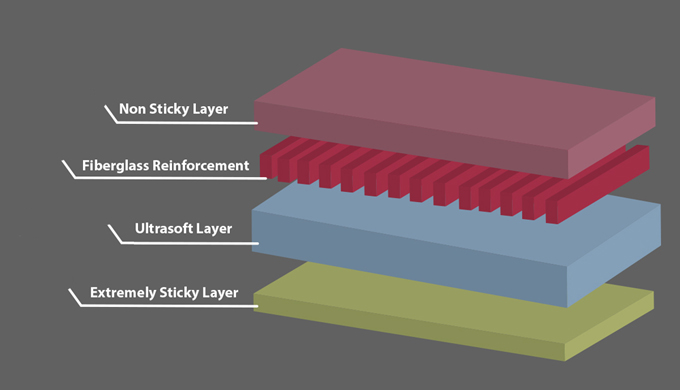

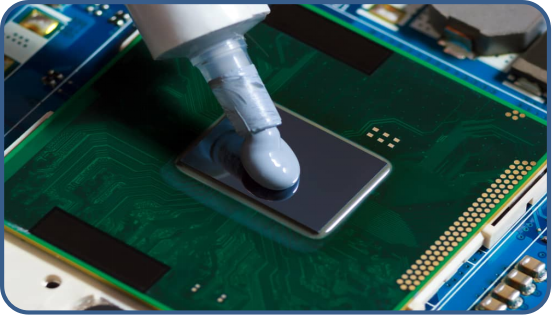

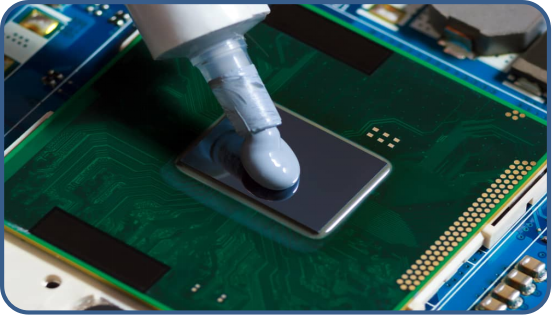

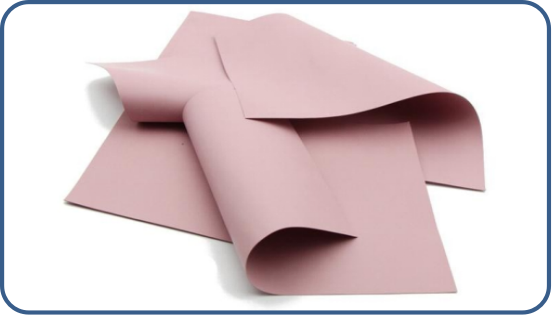

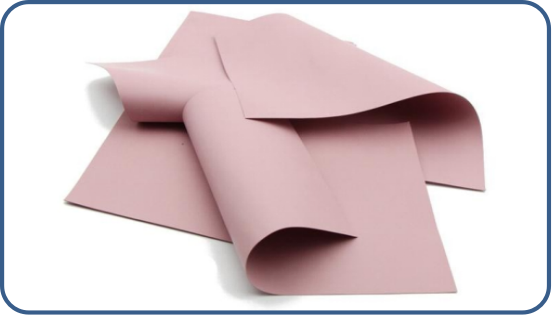

Designers must consider the thermal interface between each component to ensure good conductivity within the system. The interface materials most commonly used are thermal greases, gap pads, foils,PCM pads, epoxies and solders. These fill in tiny gaps between mating components to help ensure consistent contact. Each option offers its own set of advantages; however, these interfaces also come with limitations that designers must consider to accurately predict and optimize performance.

Importance of Cooling Medical Devices !

Thermal pads provided by SinoGuide are used in a variety of electronic applications and industries including computers, laptops, tablet PCs, smart phones, routers, LEDs, solar, medical device, power supplies, wireless devices, and the automotive industry.

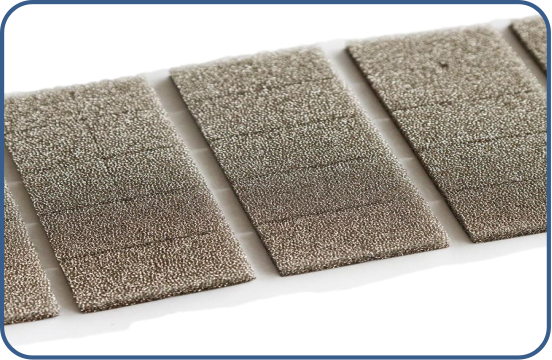

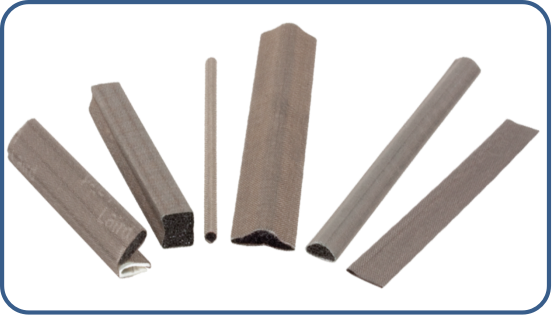

A variety of specific?compounds are available for a wide range of performance requirements in Sheets, Rolls, Die-cuts, Sleeves, Gel, Extrusions, Moldings.

Our innovative technology and extensive production capabilities allow us to manufacture reliable, easy-to-use materials at low cost and with fast deliveries.

No problems, No hassles - 100% Guaranteed Service!