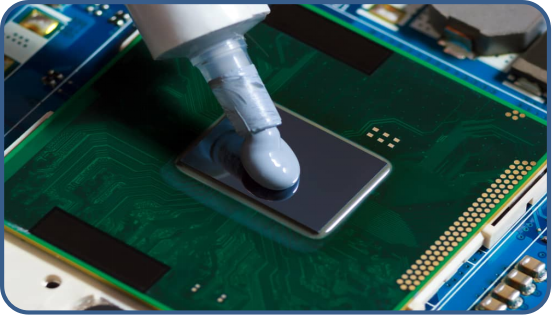

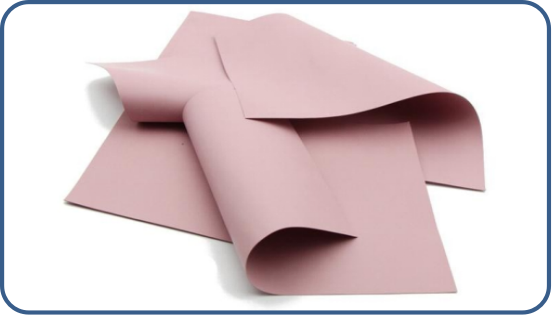

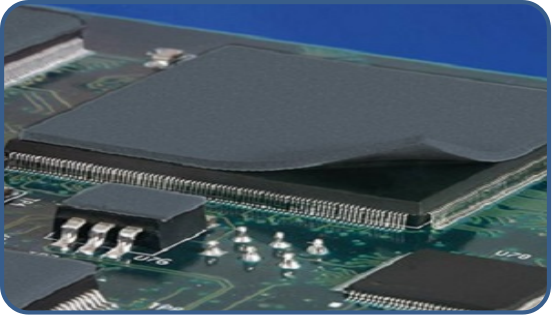

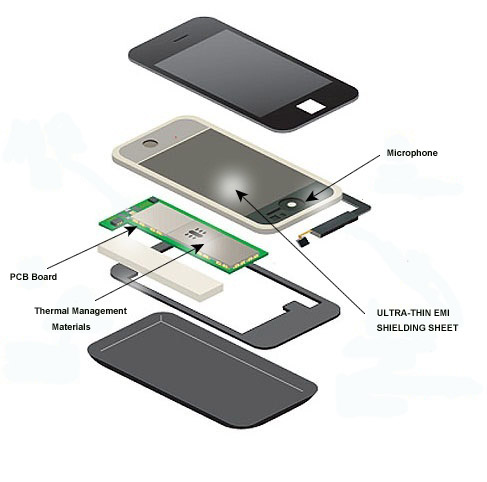

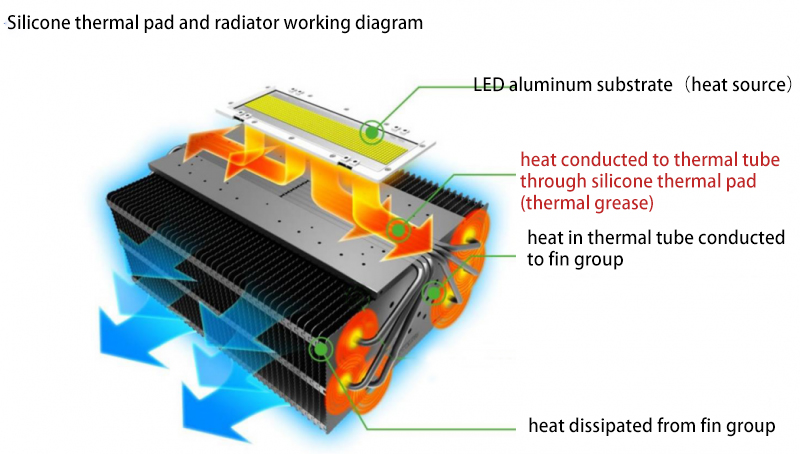

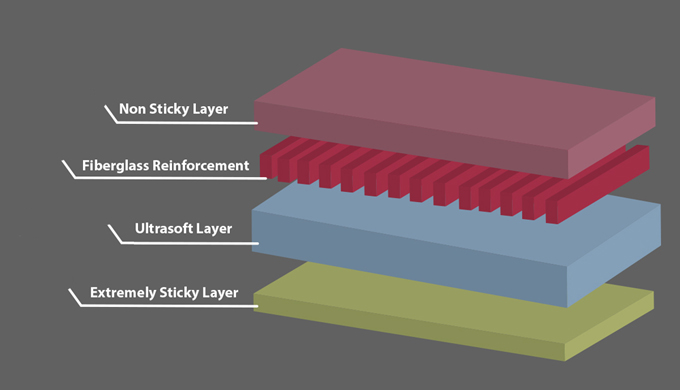

FEATURES & BENEFITS · Thermal conductivity 1.0~2.2 W/m.K · Operates at low pressure · Soft and compliable · Electrically isolating · Low volatile of siloxane for silicone sensitive appliations TYPICAL APPLICATIONS · Computer and peripherals; between CPU and heat spreader · Telecommunications · Heat pipe assemblies · RDRAM™ memory modules · CDROM / DVD cooling · Areas where heat needs to be transferred to a frame chassis or other type of heat spreader AVAILABLE OPTIONS · Standard sheet size: 18"x18" or 18"x9" · 1-side / 2-side adhesive lamination · Available in sheet / roll or precut finished parts · PI fim / fiberglass carriers are optional Typical Property PROPERTIES UNITS TSP2250 TSP2225 TSP2240LV Color - Yellow Yellow Yellow Thickness mm 0.15~10 0.15~10 0.15~10 Thermal Conductivity W/m·K 2.2 2.2 2.2 "Thermal Resistance @1mm,20psi" °C·in2/W 0.75 0.65 0.7 °C·cm2/W 4.85 4.19 4.52 Hardness Shore OO 50 25 40 Flame Rating - V0 V0 V0 Dielectric Strength kV(@1mm) >9.0 >9.0 >10.0 Volume Resistivity Ω·cm ≥3.0×1013 ≥3.0×1013 ≥3.0×1013 Density g/cm3 2.6 2.6 2.6 Tensile Strength psi 36 32 / Elongation % 55 58 / "Compression Deflection (%) at given pressure" 10 psi 12 28 15 50 psi 42 55 47 100 psi 58 86 69 Dielectric Constant @1MHz 7.5 7.5 7.5 TML(CVCM) % ≤0.32(0.08) ≤0.32(0.08) ≤0.32(0.08) Service Temp. ℃ -60~200 -60~200 -60~200 RoHS/REACH - compliance compliance compliance

LINTECH

- Search

-

Contact

- Call us:17743506620

- Address:Block 4,Shangshuijing BLG, No.333 Jihua Road, Buji Town, Longgang district, Shenzhen, P.R.China

- We reply to every email from our customers within 24 hrs. Please check your spam box if you didn t hear from us.

- 7x24hours online service

- Advance Factory in China