News and Articles

Related Product

Share Article

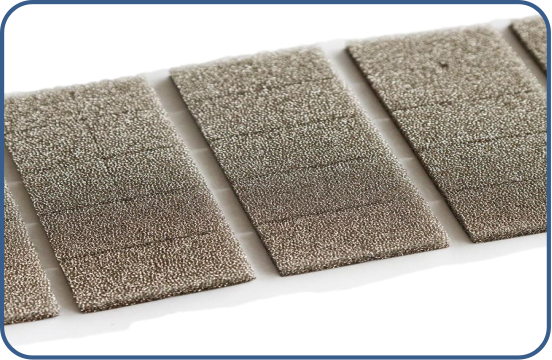

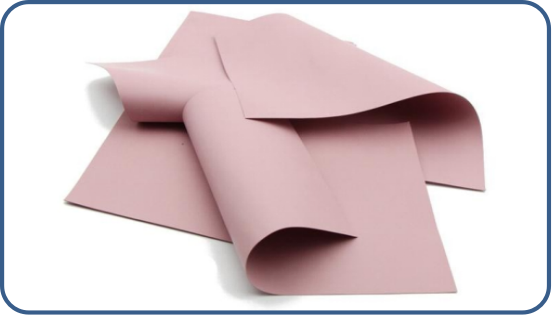

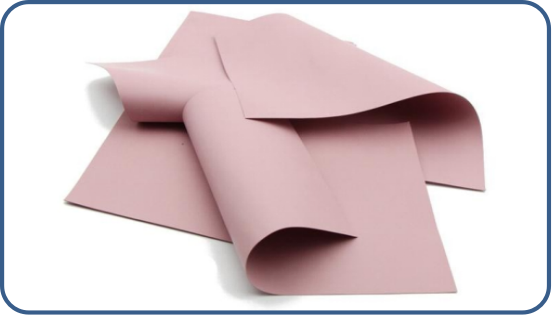

Selecting The Right Thermally Conductive Silicone Sheet

Selecting the right thermally conductive silicone sheet should keep the following points in mind to avoid stepping on potholes

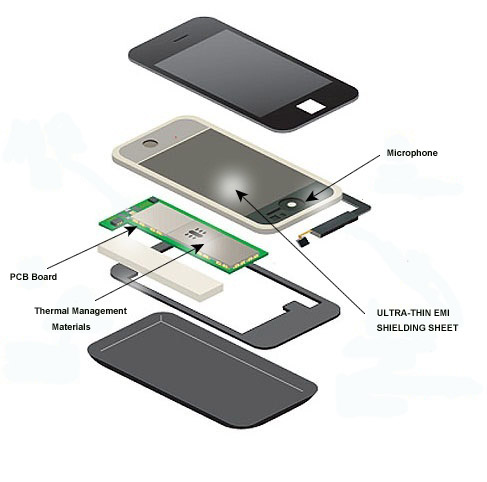

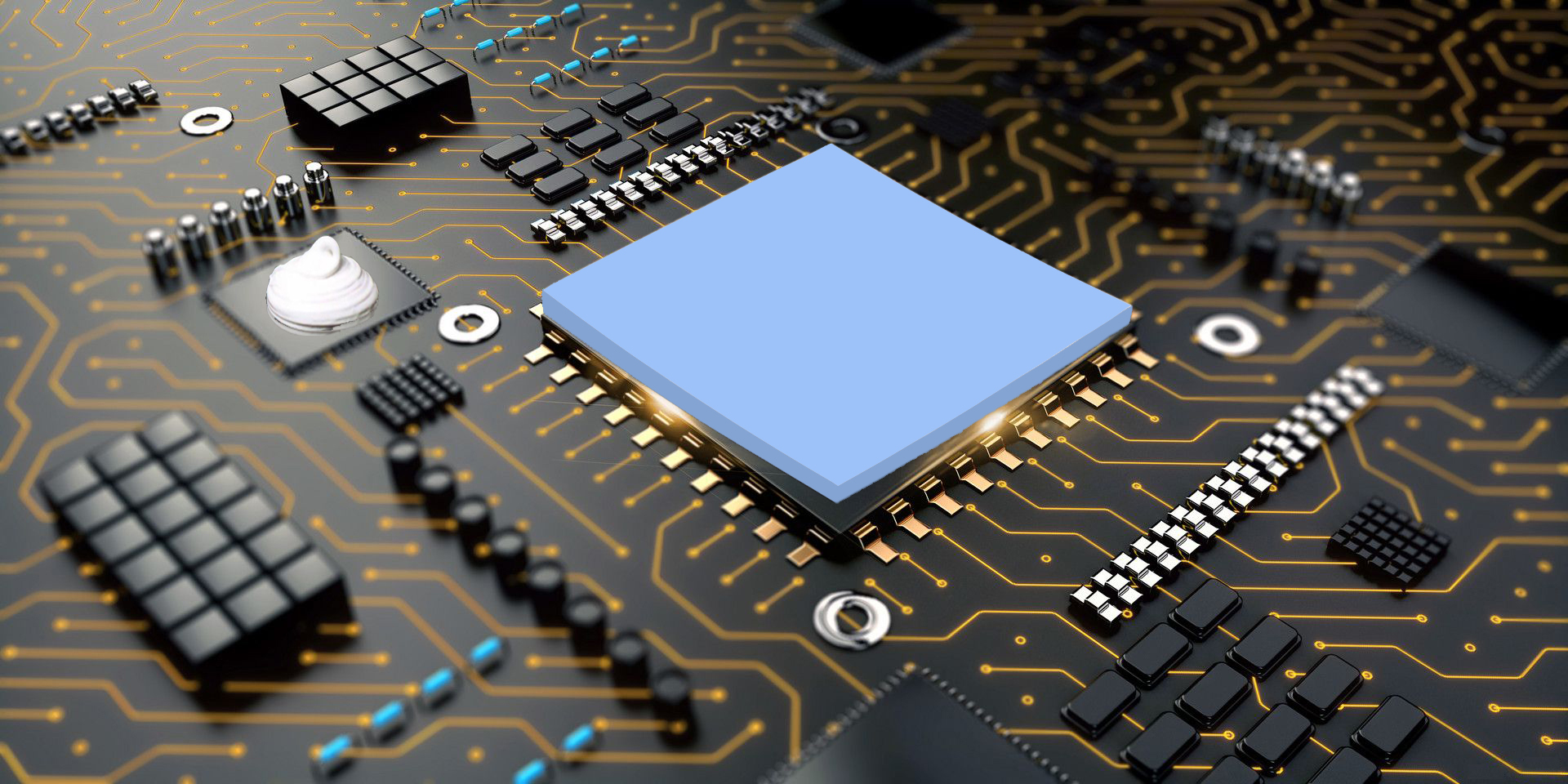

Is a product good? How well is the heat treatment problem solved? In fact, thermal conductive silicone film plays a pivotal role. But the correct choice of a suitable thermal conductive silicone film for many procurement and R & D personnel is not an easy task, because the thermal conductive silicone film itself is a functional thermal conductive media materials, we must have a certain understanding of the performance of this material in order to avoid stepping on the pits, choose the right thermal conductive silicone film. Today, Lintech Materials editor will discuss with you to choose the right thermal conductive silicone film to keep in mind a few points.

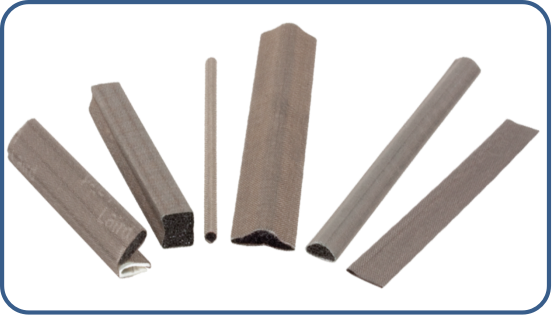

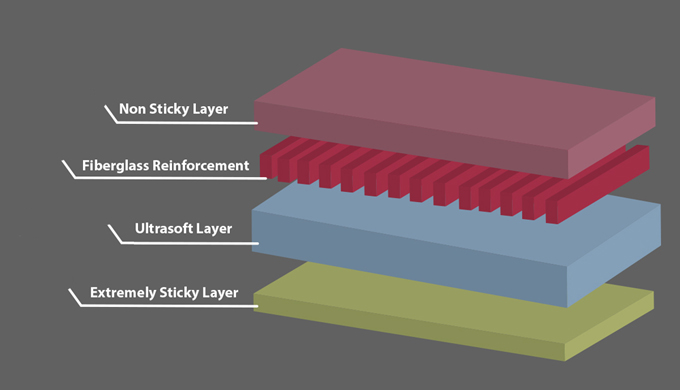

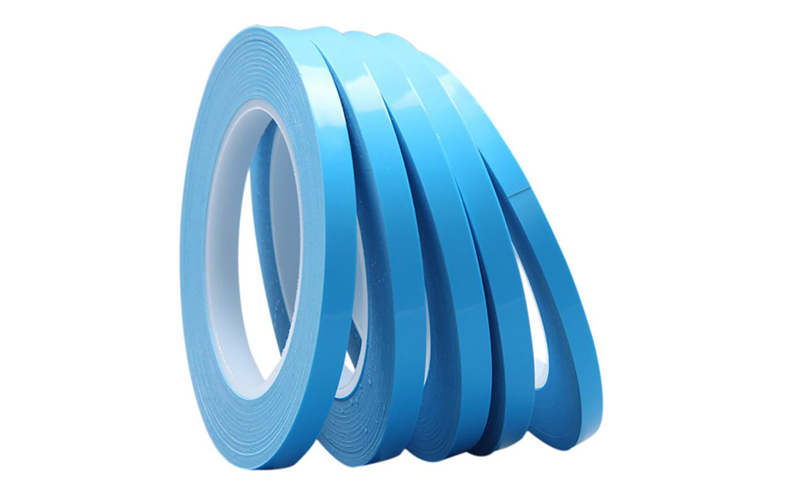

First, on the choice of thickness of thermally conductive silicone film

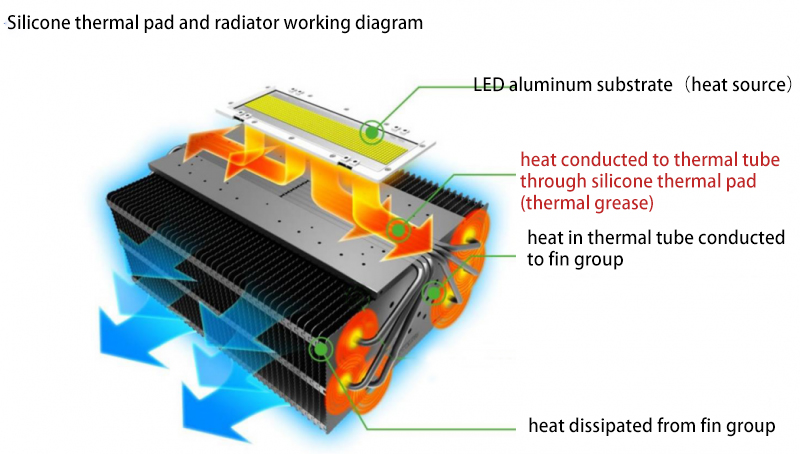

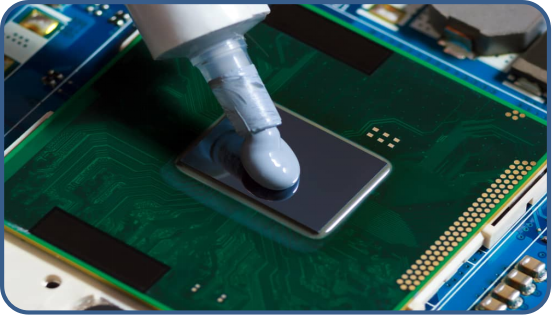

A product, from the early stages of design, in addition to the appearance of the product, but also take into account the heat treatment of the product. As we all know, the thermal conductive silicone film is used between the heat source and the radiator, plays a role in the conduction of heat, so the product in the design, you should leave a good gap between the heat source and the radiator. How much gap is appropriate? Thermally conductive silicone film the thinner the thermal conductivity effect is better, so the gap should not stay too big, too can not stay too small, taking into account the construction of thermal conductive silicone film, too thin thermal conductive silicone film in the construction of easy to break the deformation, usually thermal conductive silicone film thickness of 0.5mm-1.0mm is ideal, plus about 80% of the compression, so the gap between the heat source and the radiator is 0.3mm-0.8mm is ideal. 0.8mm is ideal. If the product structure has been designed, then according to the actual gap between the heat source and the heat sink to choose the thickness of the thermal conductive silicone film, usually, the thickness of the thermal conductive silicone film should be greater than the actual gap of about 20% is appropriate.

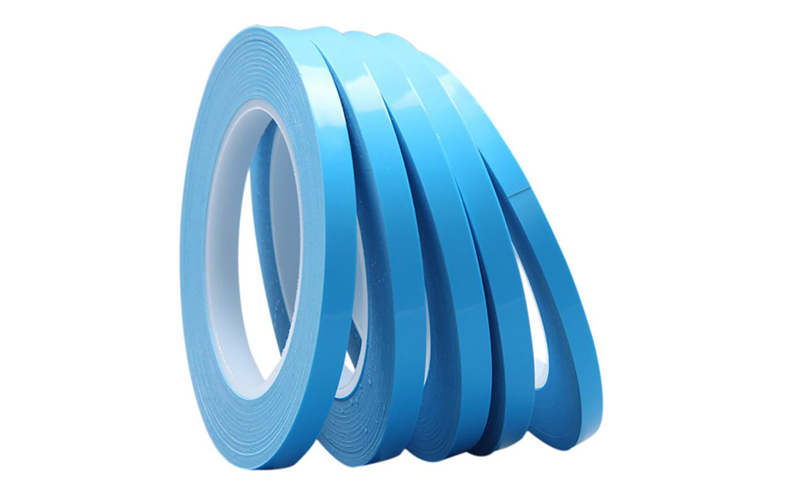

Second, on the choice of thermal conductivity of silicon film thermal conductivity coefficient

Thermal conductivity is a very important performance parameters of the thermal conductive film, in the case of other performance parameters are the same, the higher the thermal conductivity coefficient of the thermal conductivity effect is better. But we are choosing the thermal conductivity of silicon film, not that directly choose the highest thermal conductivity can be, because the higher the coefficient of thermal conductivity of silicon film, the more expensive, which will lead to increased product costs. We should be based on the power of the product itself, choose to meet the product heat dissipation needs of the thermal conductive silicone film can be, not the pursuit of high thermal conductivity.

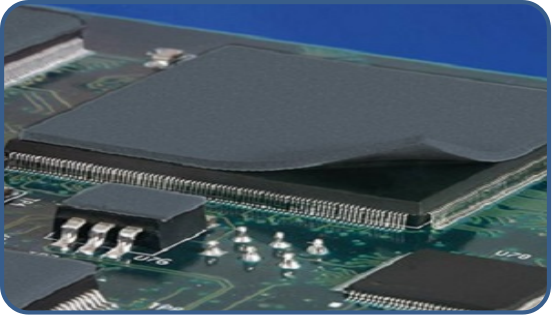

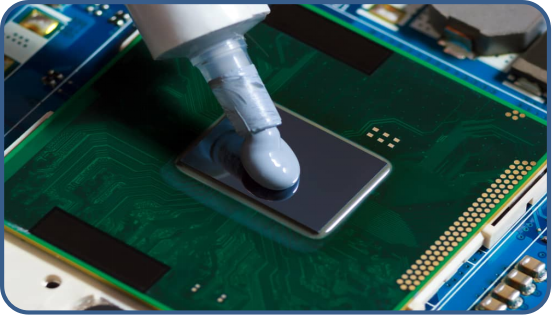

Third, on the choice of thermal conductive silicone sheet thermal resistance

In the selection of thermally conductive silicone sheet, thermal resistance and thermal conductivity is equally important. Thermally conductive silicone film thermal conductivity is the same, the lower the thermal resistance, the better the thermal conductivity, so in the selection of thermally conductive silicone sheet, the lower the thermal resistance the better.

Fourth, on the choice of hardness of thermally conductive silicone film

We all know that the heat source and radiator surface is not completely flat, direct contact, there are many gaps between the heat source and the apparatus, which will affect the conduction of heat, it is necessary to use thermally conductive silicone sheet to fill these small gaps, so that the effective contact area of the heat source and radiator to maximise the heat conduction, so as to better conduct heat. To better fill the gap, naturally, we should choose a soft thermal conductive silicone film, hardness heat dissipation of low soft thermal conductive silicone film compression stress is relatively small, not easy to damage the product components.

Keeping the above points in mind, you can choose a suitable thermally conductive silicone film to avoid stepping on the pit. If there is any doubt in the selection process, feel free to consult Lintech Materials thermal conductive silicone film sales engineers, we will provide you with more professional and detailed introduction.