News and Articles

Related Product

Share Article

Difference Between High Thermal Conductivity Sheet and Silicone-free Thermal Conductivity Sheet

Information Summary:

Silicon free thermal conductive sheet and high thermal conductive silicone sheet are thermal conductive interface materials, both have high thermal conductivity and soft heat dissipation. But the two are still different in practical application, what are the differences between them? Today...

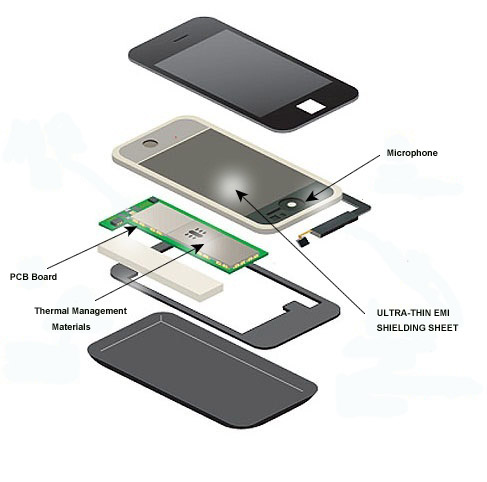

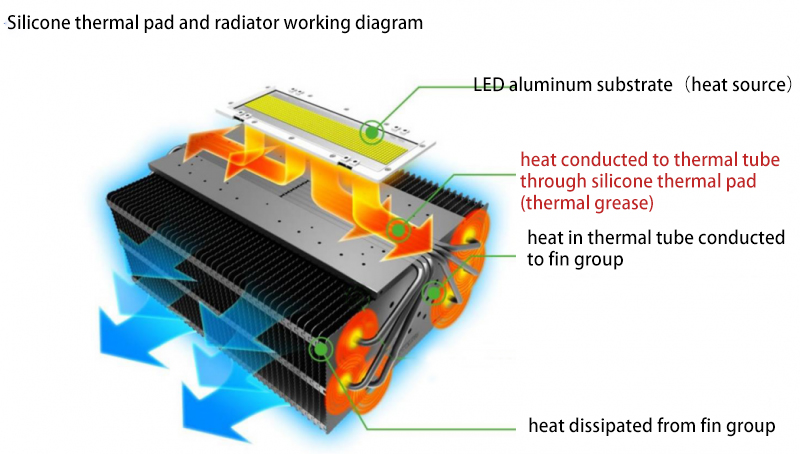

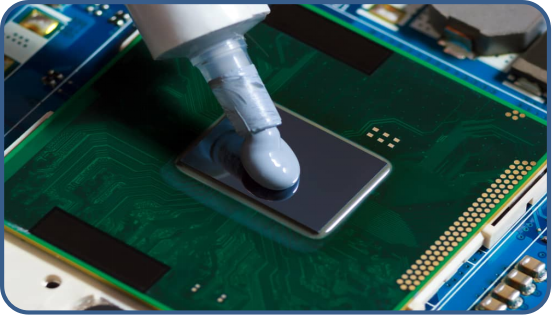

Heat dissipation is the focus of product design, because heat production is the commonality of electrical equipment, high temperature equipment within the electrical components are prone to failure, and there may be a loss of the service life of the equipment, and thermal conductivity gap-filling material is a kind of equipment that can effectively reduce the equipment between the heat source and the heat sink contact thermal resistance, to exclude the air in the gap, so as to improve the effect of the equipment's heat dissipation.

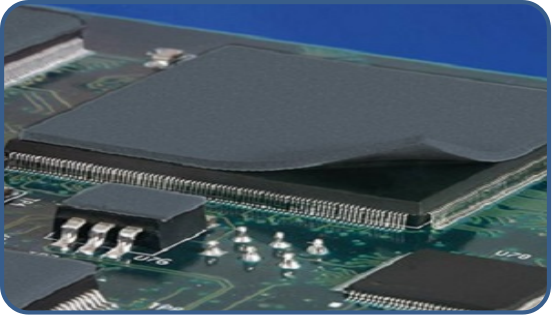

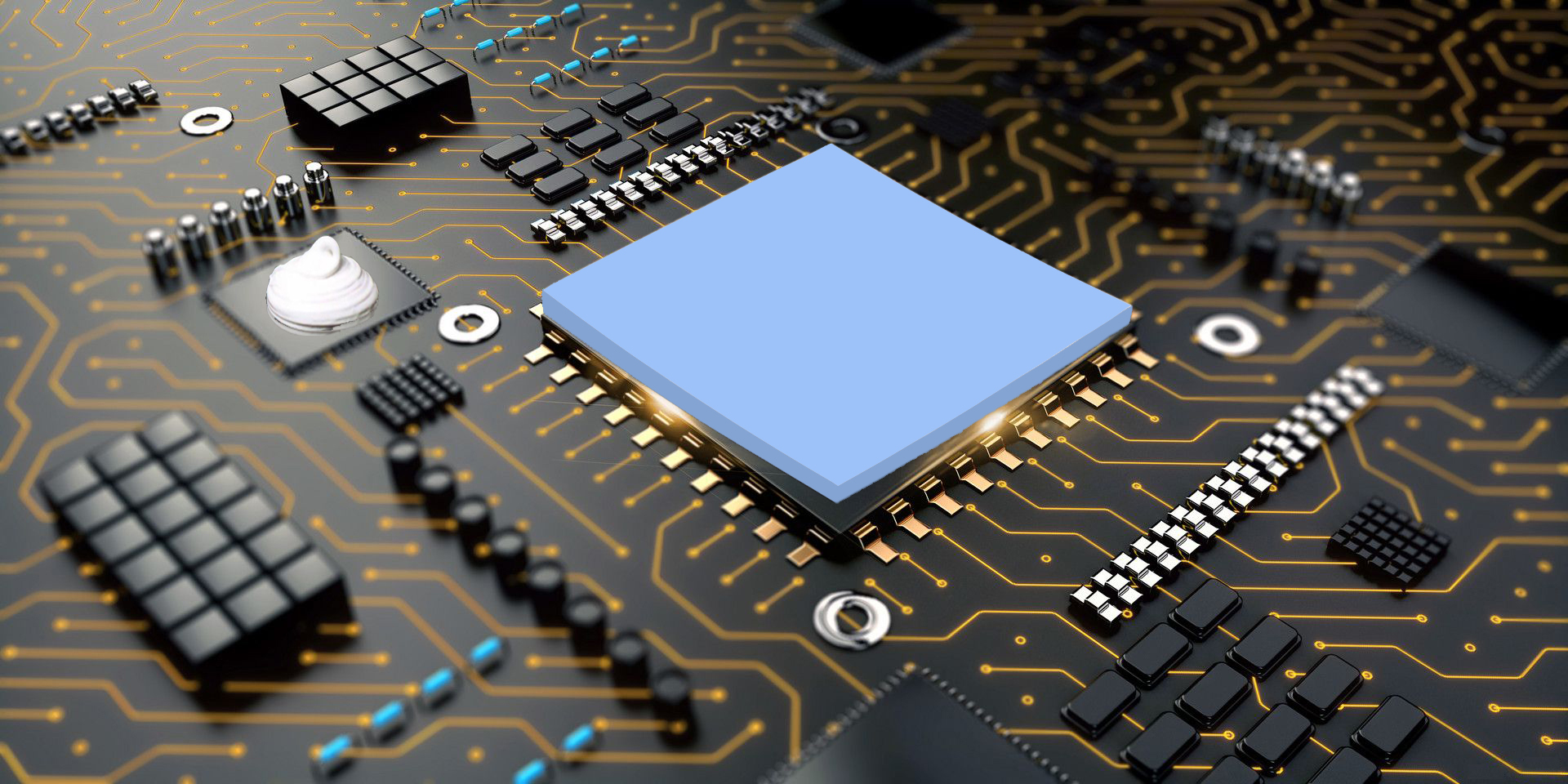

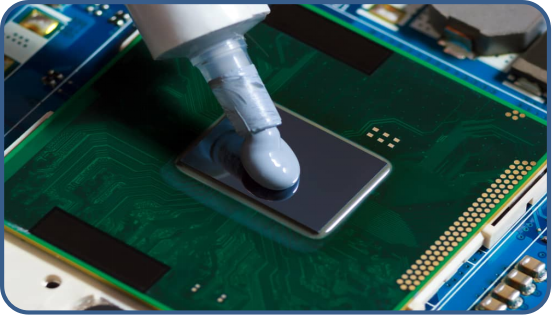

Thermal conductive silicone sheet is a silicone-based thermal conductive material, with Excellent high thermal conductivity and flexibility, by filling the interface of the components of the tiny The air is discharged through filling the tiny gaps at the interface of the components, increasing the contact area with the heat sink to reduce the thermal resistance value. The purpose is to reduce the thermal resistance value. As an ideal thermal conductive material in the field of thermal management, it is widely used in LED lighting, energy As an ideal thermal conductive material in the field of thermal management, it is widely used in LED lighting, energy automobile, communication equipment, power supply module, industrial control equipment and other industries. As an ideal thermal conductive material in the field of thermal management, it is widely used in LED lighting, energy automotive, communication equipment, power supply modules, industrial control equipment and other industries. Usually silicone film raw materials will add a small amount of silicone oil to enhance the performance of long-term exposure to high temperatures. In the high temperature environment will lead to fine oil seepage, silicone oil will not only cause electronic motherboard contamination, and volatile atomization will even affect some important electronic components. electronic components.

Silicone-free thermal conductive sheet and high thermal conductivity silicone sheet are thermal interface materials, both have high thermal conductivity and soft heat dissipation. But the two are still different in practical application, what are the differences between them? Today I bring you to explore these two materials, very lucky Lintech these two materials are produced.

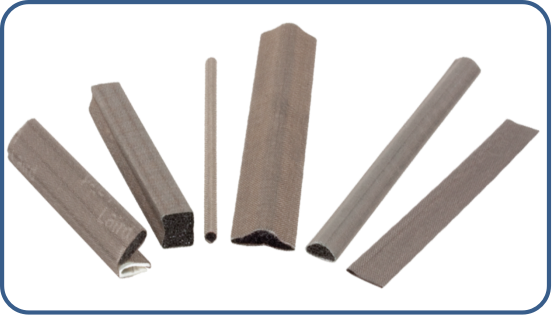

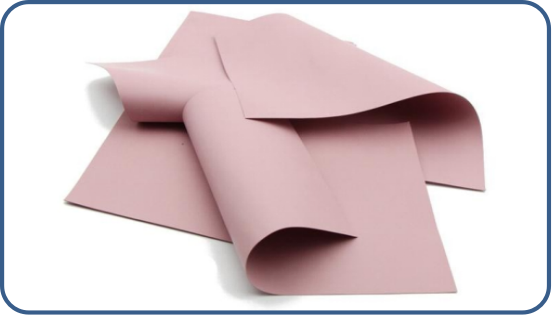

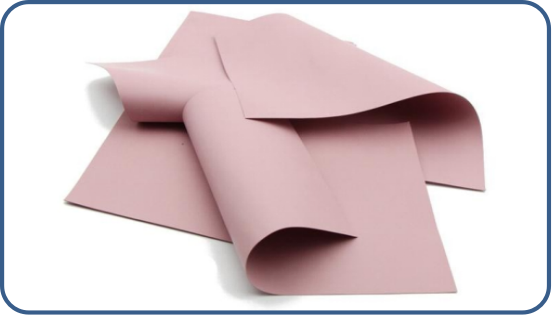

Characteristics and applications of silicone-free thermal conductive sheet:

1, good durability and long time to maintain flexibility, with high thermal conductivity, can quickly transfer heat to the heat sink;

2、No low molecular weight siloxane gas is generated, which leads to contact damage of the substrate and other components;

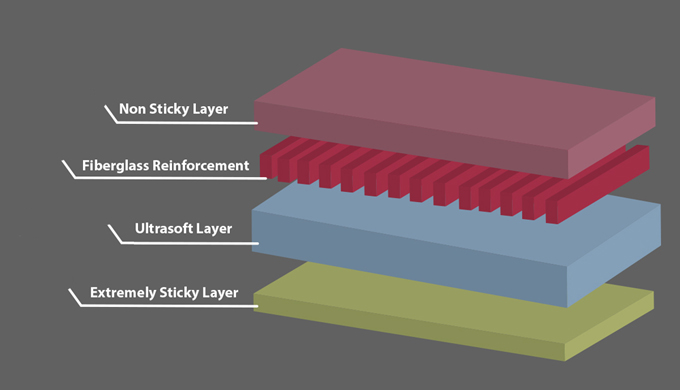

3、Since the top layer has a non-adhesive layer with low ductility, it is superior in processability and reprocessability;

4、Halogen free with high level of flame retardancy.

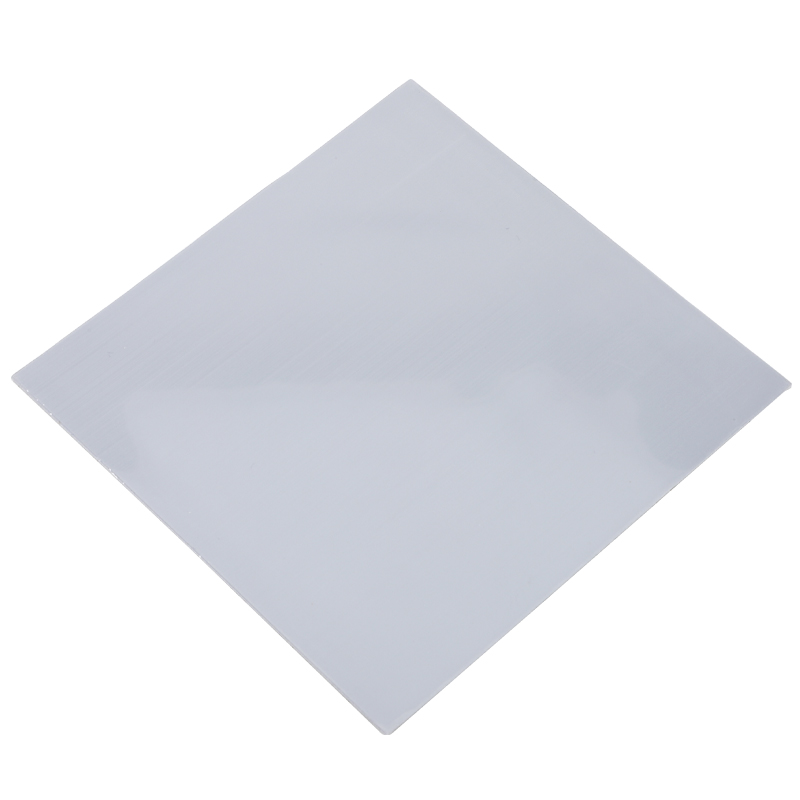

Characteristics and applications of high thermal conductivity silicone sheet:

1, with high flexibility and high thermal conductivity, can quickly transfer heat to the heat sink;

2, with low molecular weight silicone gas volatility, even if long time use can contact the risk of failure to a low degree;

3、Halogen free, with a high level of flame retardancy;

4, low viscosity two-layer structure realizes high processability and reprocessability.

Thermally conductive silicone

In fact, the two characteristics of the comprehensive view, the two thermally conductive interface materials are not very different, more just in some aspects more suitable for the application of it. For example, like cameras, industrial cameras use more silicone-free thermal conductive sheet, silicone-containing lenses are prone to fogging.

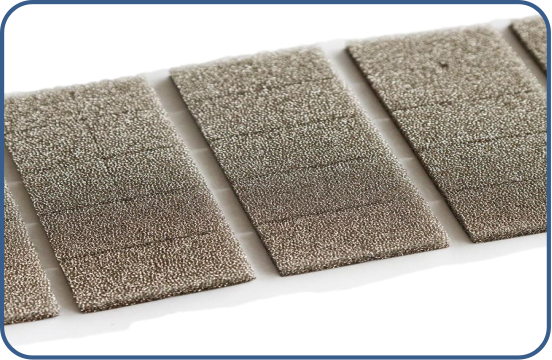

TSP-NS series silicone-free thermally conductive gaskets are designed and developed for silicone-sensitive applications and a high thermal conductivity, high strength, flame retardant interface thermal conductive materials, developed for different applications of a number of models to meet the high compression, multiple rework, tear resistance, high-frequency vibration and impact and other applications.